Plastic Engine Auto Accessories Vacuum Formed Thermoformed Car

Spare Parts

| Product range | Mold design, mold making and produce plastic parts |

| Material of mold | P20, SKD61, 718H and so on, which you can choose. |

| Mold frame | 45 Pre-hardened>30HRC |

| Cooling system | recirculation |

| Medium-term treatment | Improve the hardness |

| Die life | 300000 shots, 500000 shots |

| Post-processing | Nitride |

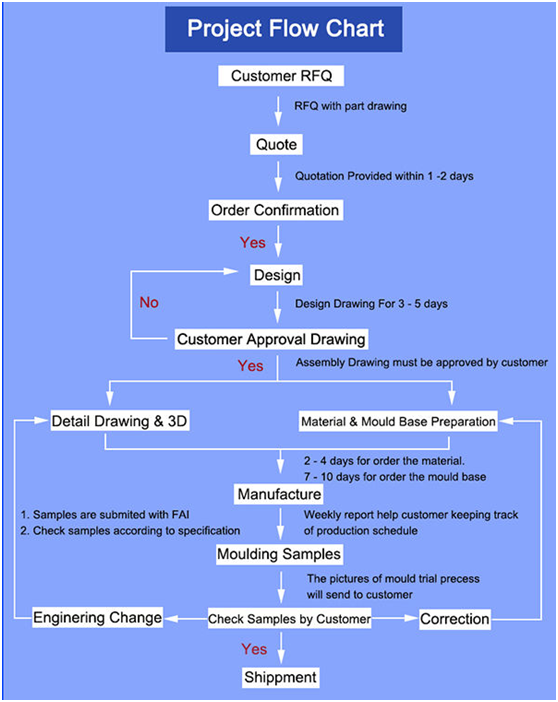

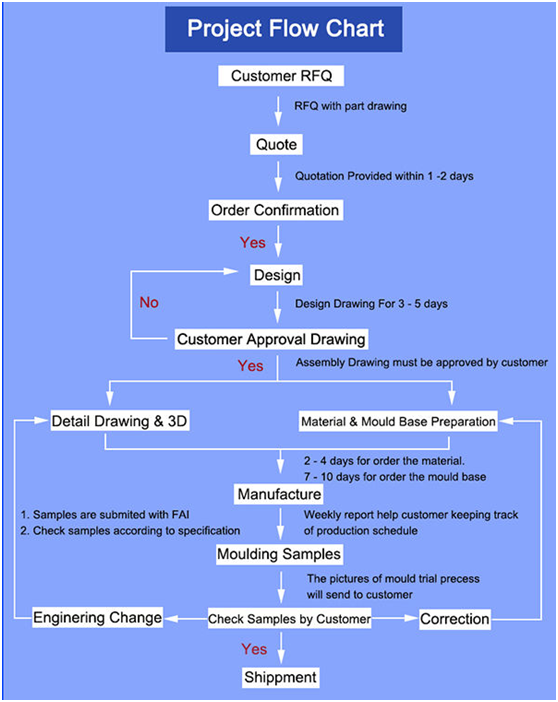

| Mold processing technology | Review plan --- stock preparation --- processing --- rough mold

base --- punching machine --- EDM die sinking --- die machining ---

inspection --- assembly --- flight mode --- tryout ---customer

confirm sample ---delivery |

| Runner system | 1 point gate hot runner |

| Ejection system | Inclined ejecting block |

| Moulds running | Full automaticity |

| Moulds features | Complex mould structure. Etc. |

| Injection cycle time: | 12s, 15s, 18s, 20s, 22s, 25s(high speed injection machine) |

| Cavity | Single/multifunction |

| Mould life | 30000-500000 Shots |

| Delivery time | 15-60 working days |

PP introduction

1. the relative density is small, only 0.89-0.91. it is one of the

lightest varieties in plastics.

2. good mechanical properties, except impact resistance, other

mechanical properties are better than polyethylene, molding and

processing performance.

3. with high heat resistance and continuous use temperature of

110-120 ℃.

4. the chemical performance is good, almost does not absorb water,

and most chemicals do not react.

5. pure texture, non-toxic.

6. Good electrical insulation. The transparency of polypropylene

products is better than that of high-density polyethylene products.

PE introduction PC introduction

1. High strength and elastic coefficient, high impact strength and

wide range of temperature.

2. high transparency and free staining.

3. The forming shrinkage is low and the dimension stability is

good.

4. good fatigue resistance.

5. good weather resistance.

6. excellent electrical characteristics.

7. odorless, tasteless.

ABS introduction

Good comprehensive performance, high impact strength, chemical

stability, good electrical properties, can be surface chrome, spray

treatment; It has high impact resistance, high heat resistance,

flame retardance, enhancement, transparency and so on. Good

flexibility; is suitable for making general mechanical parts,

wear-resistant and wear-resistant parts.

PA6 PA66 introduction

1. Nylon has high mechanical strength and good toughness.

2. Self-moisturizing, good friction resistance. Nylon has good

self-moistening, low friction coefficient, thus, as a transmission

component its long service life.

3. Excellent heat resistance, PA66 can be reinforced by glass

fiber. The thermal deformation temperature is above 250 ℃.

4. Excellent electrical insulation. Nylon volume resistance is very

high, high breakdown voltage, is an excellent electrical,

electrical insulation materials.

FAQ:

1.Q: How do I purchase your goods?

A: Please send us the inquiry, call us your need, we will reply

ASAP.

2.Q: Can I check the quality of goods before delivery?

A: Yes, you come to our factory, or ask your colleagues in your

Chinses office or even ask a third party inspection company to

check the quality before delivery.

3.Q: If we invest in mold, but the sample is not satisfying, what

should we do?

A: We will make mold strictly according to the drawing or samples,

if the first sample is not satisfied, we will modify mole until you

are satisfied.

4. Q: What is your main product?

A: We build plastic injection mold and die-casting mold, as well as

making mass production.

5.Q: What is the material of your product?

A: PP, PS, PVC, PET, PE, ABS and some other material.

6.Q: Can you help with the design?

A: Yes, we can accept your customization and do the packaging for

you according to your requirement

7.Q: How can I get the quotation of the Custom products?

A: Send us the 2D/3D drawings or send us your sample products, and

then we can offer you a quote.

8.Q: Can I get some samples before making a bulk order?

A: Yes, the free sample can be sent, but the shipping fee should be

paid by yourself.

9.Q: Do you have MOQ?

A: Yes, we have. but different products will have different MOQ, so

let us know which product you like firstly.

10.Q: Could I put my logo on the products?

A: Yes, we can put your logo on the products, show us your logo

firstly please.

If you have any questions, please feel free to contact me, thanks

in advance!