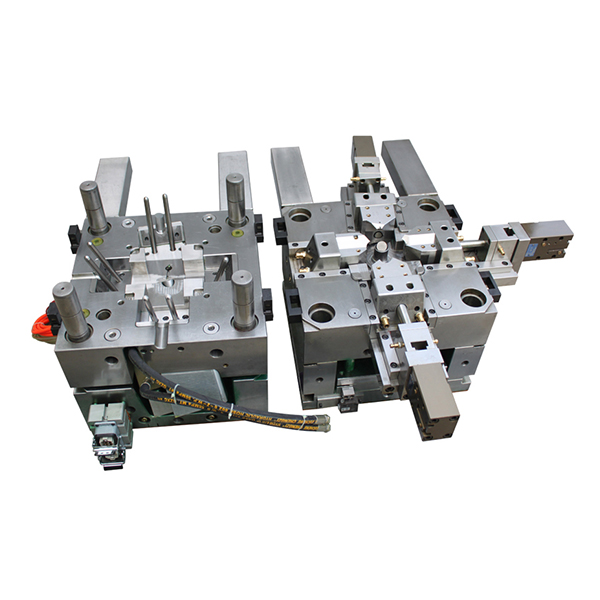

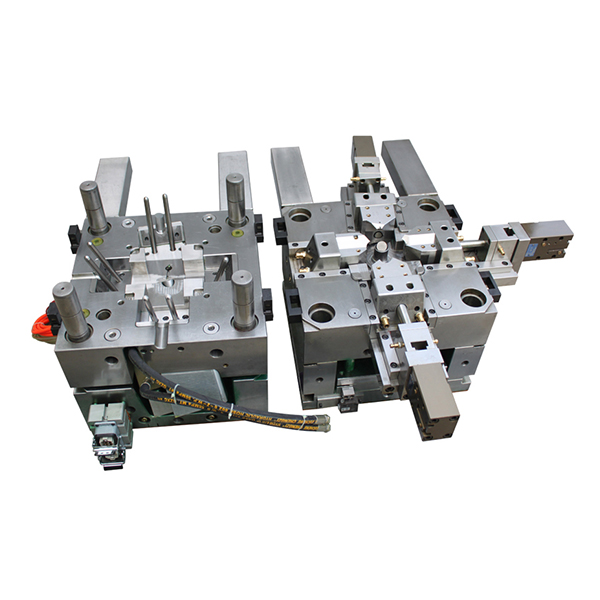

Various Type Auto Plastic Injection Parts Lamp Mould Car Bumper

Mold

Mould Information:

| Main Technique Parameters |

Cavity/Core

Material | 718H, P20, NAK80, 2316,2738,Din2344,H13 and available |

| Product Material | ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA,

PBT, PEI, etc. |

| Base | LKM or by requested |

| Structure | Double color injection mould, Solid Mould, Insert Mould, Mould with

Slide, Mould with Lifter |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi-cavity by requested |

| Finish | Corrosion word, Mirror finish, Brushed |

| Longevity | 0.5-1 million shots |

| Mould standard | HASCO, DME, MISUMI, or by requested, etc. |

| Software | CAD, Pro-E, UG, etc |

| Tolerance | ± 0.05mm |

| Design Time | 3-7days |

| Sample time | 3-7days |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5

Dimension test, etc. |

| Production time | 2-7 weeks, depends on mould structure |

| Packing | Wooden case, PE, or by request |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores &

cavities, the weight of products, part cost, payment, moulds

lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM,mold flows and mold detail agreed

with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold

progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15

pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirements. |

| 8. Delivery | deliver goods by air or by sea. |

Material:

Injection mold material: 718H, 738, SKD-61, NAK80, S136, S136H,

8407, hardness 46-50, heat treatment

Die casting mold material: S 8407, hardness 48-52, Japan SKD-61.

Plastic Material:

ABS,AS,PP,PPS,PC,PE,PEI,PES,POM,PMMA,PS,HDPE,TPE,TPU etc.

Alloy material: zinc alloy, aluminum alloy, magnesium alloy

Machines:

Many machine tools are imported from America and Japan, which can

ensure the processing precision, good quality.they are plastic injection machines, die-casting machines. High-speed CNC

machines centers. CNC engraving and milling machine, mirror plane

EDM. Low-speed wire cutting machines. Deep hole drilling machine.

EDM machines. Milling machines. Grinding machines. 3-D and 2.5-D

Coordinate Measuring Machines.

Injection Mould Description:

Most thermoplastics can be processed by Injection Moulding. It is

used to produce all kinds of plastic parts for a wide variety of

applications, commonly such as plastic housings or body protectors,

boxes, trays, cups, mats, caps, fittings containers, buckets and so

on.

Such as household appliances, consumer electronics, power tools,

automotive dashboards. Power-tool housing, Disposable razors,

Electrical Switches, Crates/Recycling boxes, Automotive dashboards,

Television Cabinets, Drug Inhalation Units, Automotive bumpers,

Wheelie bins, Syringes, Telephone handsets, Washing-up bowls, DVDs

player, Bottle Lids/closures, Battery Casings,

Injection molding is also used to produce several everyday items

such as toothbrushes or small plastic toys. Many medical devices,

including valves and syringes, are manufactured using injection

molding as well.

FAQ:

1. What is your business?

A. Precision Plastic Mold manufacture

B. Medium and large plastic mold manufacture

C. Injection molding

D. professional designing and making

E. R&D service

2. How about tolerance?

Mold tolerance is 0.005 mm, Product tolerance is 0.02 mm.

3. What steel do you usually use?

We usually use steel of P20, P20H, H-13,O-1,S-7,420,420H,D2, NAK80,

1.2311, 1.2711,1.2344,1.2510,1.2083,1.2316 and 1.2379.

4. What standard components do you usually use?

We use standard components from LKM, DAIDO, HASCO, DME. (Hot

Runner: MOLD MASTER, HUSKY, DME, HASCO, INCOE, THERMOPLAY, YUDO.)

5. What do you need for a quotation?

We need 2D part drawing & 3D drawing, and specific mold or part

requirements.

2D File Format dwg /dxf /pdf/jpg ,3D Model Format step /x_t /igs

/prt

6.How about your mold payment terms?

Mold payment terms:40%-30%-30%.The first payment is when you sign

the order, you should pay us 40% of the total value; the second

payment is when you receive our sample product, you should pay us

30% of the total value; the last payment is when we deliver the

mold for you, you should pay off the balance payment,30% of the

total value.

7. How about your part payment terms?

Part payment terms:50%-50%.The first payment is when you sign the

order, you should pay us 50% of the total value to purchase the

material; The last payment is when we deliver the part for you, you

should pay off the balance payment,50% of the total value.

8. What’s your after-sales?

After-sales: Our customer’s mold drawings and the whole data will

be kept in a database for 5 years at least.so that when you need

our technical support or service, we can be easy and possible to

serve you and your customers.