Car Customized making engineering auto parts plastic injection mold

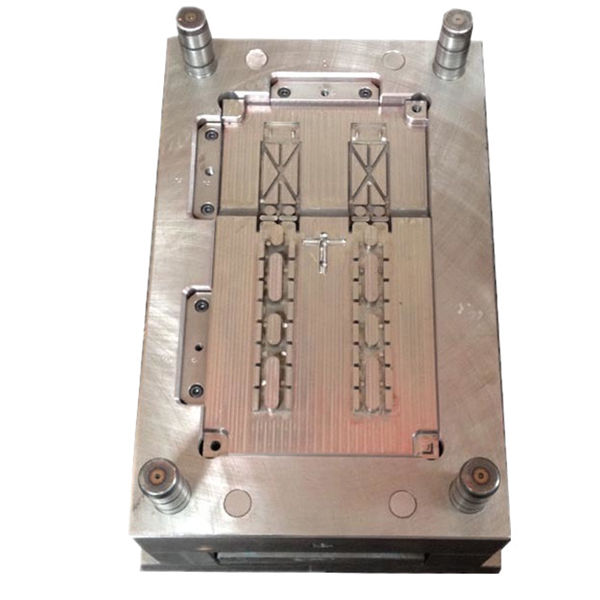

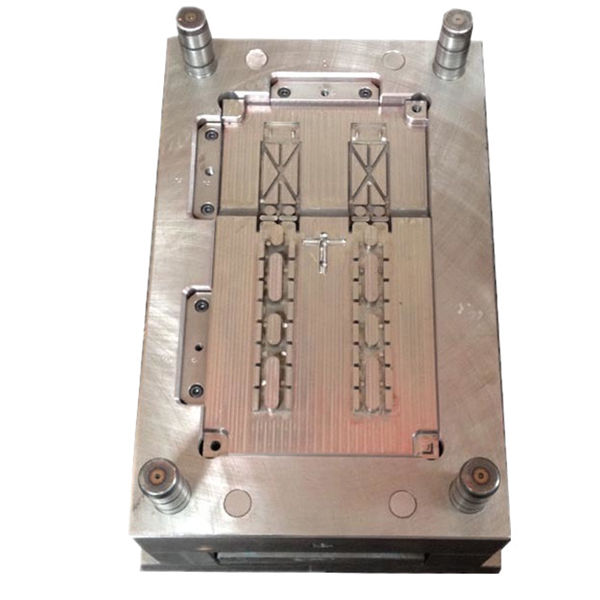

Mould Information:

| Main Technique Parameters |

Cavity/Core

Material | 718H, P20, NAK80, 2316,2738,Din2344,H13 and available |

| Product Material | ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA,

PBT, PEI, etc. |

| Base | LKM or by requested |

| Structure | Double color injection mould, Solid Mould, Insert Mould, Mould with

Slide, Mould with Lifter |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi-cavity by requested |

| Finish | Corrosion word, Mirror finish, Brushed |

| Longevity | 0.5-1 million shots |

| Mould standard | HASCO, DME, MISUMI, or by requested, etc. |

| Software | CAD, Pro-E, UG, etc |

| Tolerance | ± 0.05mm |

| Design Time | 3-7days |

| Sample time | 3-7days |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5

Dimension test, etc. |

| Production time | 2-7 weeks, depends on mould structure |

| Packing | Wooden case, PE, or by requested |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores &

cavities, the weight of products, part cost, payment, moulds

lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM,mold flows and mold detail agreed

with the customer, start production. |

| 5. Production schedule | Every week we will provide feedback to the customer mold

progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15

pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your

requiretments. |

| 8. Delivery | deliver goods by air or by sea. |

FAQ:

A. We usually quote within 24 hours after we got your inquiry. If

you are very urgent to get the price, please call us or tell us in

your email so that we will regard your inquiry priority.

Q. How can I get an accurate price?

A. There are some basic specs we need to know for price

calculation, that is: 3D drawings in STP, IGS, X-T format are

available, Please suggest to us your quantity too.

Q. Do you accept the OEM?

A. OEM is welcome. We can custom the goods according to your

design.

Q. What is the shipping?

A: By express(FedEx, UPS, DHL, TNT, EMS, etc...), By Air, by

shipping.

Q. How do I pay for the order?

A. The common payments are T/T(Telegraphic Transfer), western

union,

Q. I have an idea for a new product, but I don't know if it can be

manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to

evaluate the technical feasibility of your idea or design and we

can advise on materials, tooling, and likely set-up costs.

Q. What are the advantages of having my parts manufactured locally?

A. We can offer quick reaction times to any changes in

specification, batch size or material.

Q. My components have already been developed on CAD. Can you use

the drawings?

A. Yes! DWG, DXF, IGES, Solidworks, and Rhino files can all be used

to generate quotes, models, and mould tools - this can save time

and money in producing your parts.

Q. Can I test my idea/component before committing to mould tool

manufacture?

A. Yes, we can use CAD drawings to make models for design and

functional evaluations.

Q. What type of plastic is best for my design/component?

A. Materials selection depends on the application of your design

and the environment in which it will function. We will be happy to

discuss the alternatives and suggest the best material.

Q. What type of mould tool do I need?

A. Mould tools can be either single impression (one part at a time)

or multi-impression (2,4, 8 or 16 parts at a time). Single

impression tools are generally used for small quantities, up to

10,000 parts per year whereas multi-impression tools are for larger

quantities. We can look at your projected annual requirements and

recommend which would be best for you.

Q. Ok, I've decided to go ahead with my project. How long will it

take to get my parts?

A. It can take 3-8 weeks to have the mould tool manufactured

depending on the part's complexity and the number of impressions

(single or multi). After we have received final approval by you of

the new tool, you can expect delivery of parts within 2-3 days.