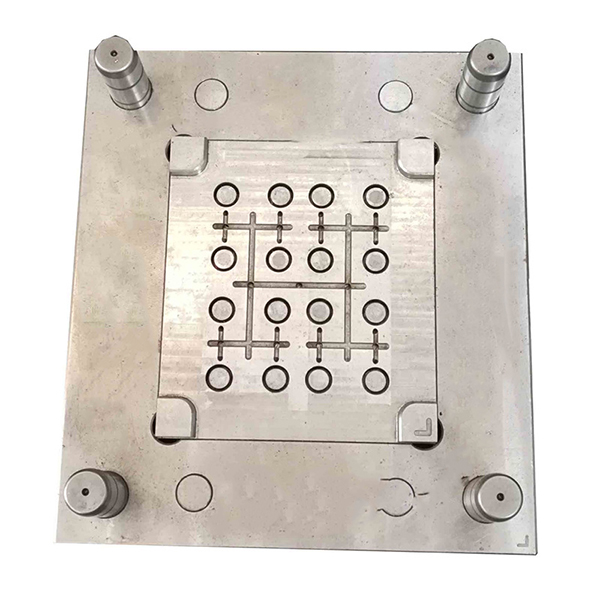

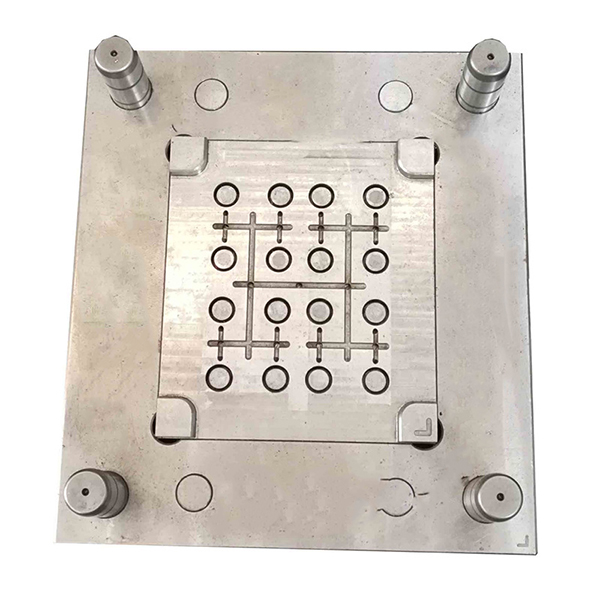

Custom injection molding for Auto Multimedia plastic injection mold

Mould Information:

| Mould material | plastic |

| Cavity | 1 cavity, 2 cavities or multi-cavity |

| Runner | hot runner or cold runner |

| Mould life | 300,000-500,000 shots |

| Processing methods | forgings, CNC milling and turning, grinding, casting, broaching,

etc |

| Design software | NX-UG, Pro/E, Moldflow, Auto CAD |

| Hardness of steel | 46~56HRC |

| A surface request | EDM&High polish |

| Payment terms | T/T, L/C, Paypal, and Western Union |

| R&D | 1: drawing design and making for products and mold; 2.mould drawing

revising |

| Production | pilot run production and molding production can be provided |

| Specification | 6 years machining parts processing experience; precision tolerance

less than 0.001mm; depends on customers’ requirement |

| Processing equipment | CNC machine, Automatic lather machine, EDM machine, stamping

lathes, wire-cutting machine, milling/grinding machine,

punching/drilling machine, Ultrasonic cleaning machine, etc. |

| Detection equipment | Projector, Calliper, Height gauge, screw gauge, hardness gauge, etc |

| Plastic Mold production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores

& cavities, t he weight of products, part cost, payment, moulds

lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM, mold flows and mold detail agreed

with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15

pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your

requiretments. |

| 8. Delivery | deliver goods by air or by sea. |

Material:

Injection mold material: Sweden 718, 718H, 738, SKD-61, NAK80,

S136, S136H, 8407, hardness 46-50, heat treatment

Die casting mold material: Sweden 8407, hardness 48-52, Japan

SKD-61.

Plastic Material:

ABS,AS,PP,PPS,PC,PE,PEI,PES,POM,PMMA,PS,HDPE,TPE,TPU etc.

Alloy material: zinc alloy, aluminum alloy, magnesium alloy

Machines:

Many machine tools are imported from America and Japan, which can

ensure the processing precision, good quality.they are plastic injection machines, die-casting machines. High-speed CNC

machines centers. CNC engraving and milling machine, mirror plane

EDM. Low-speed wire cutting machines. Deep hole drilling machine.

EDM machines. Milling machines. Grinding machines. 3-D and 2.5-D

Coordinate Measuring Machines.

Injection Mould Description:

Most thermoplastics can be processed by Injection Moulding. It is

used to produce all kinds of plastic parts for a wide variety of

applications, commonly such as plastic housings or body protectors,

boxes, trays, cups, mats, caps, fittings containers, buckets and so

on.

Such as household appliances, consumer electronics, power tools,

automotive dashboards. Power-tool housing, Disposable razors,

Electrical Switches, Crates/Recycling boxes, Automotive dashboards,

Television Cabinets, Drug Inhalation Units, Automotive bumpers,

Wheelie bins, Syringes, Telephone handsets, Washing-up bowls, DVDs

player, Bottle Lids/closures, Battery Casings,

Injection molding is also used to produce several everyday items

such as toothbrushes or small plastic toys. Many medical devices,

including valves and syringes, are manufactured using injection

molding as well.

FAQ

Q: Can you accept OEM service?

A: Yes, we are warmly welcome OEM service. Just send your 2D&3D

drawing or golden sample with quality demand (such as material,

surface treatment, color, and package) to us.

: What is the drawing format you needed?

A: Prefer to STP, DXF for 2D&3D drawing, and PDF, AI, CDR, JPG

for artwork design.

Q: What is your MOQ?

A: Usually our MOQ is 1000pcs, but we accept lower volume for your

trial order.

Q: Can I get samples?

A: Sure, we usually provide a free store sample to you for quality

checking. 1~2days can delivery. But there is a little sample fee

that would be charged if you request your OEM samples, and it is

refundable when your order is up to a certain quantity. 3~5days can

delivery.

Q: How much is the freight charge?

A: To save money and time, we suggest to deliver by express for

small quantity, and deliver by sea for large quantity. At the same

time, we can get a big discount from a shipping company.

: Do you have a quality guarantee?

A: Yes. We have QC department and 100% inspection before shipping,

to ensure the CNC parts is NO visual defects, a traceable quality

record for the product shipped from us, and if any fault is found,

we commit to send a replacement at our cost, or any other more

suitable solution depends on discussion with our customer. At the

same time, we have joined Trade Assurance in Alibaba, worry-free

shipping and quality for our customers.