Presentation_Howe Precision Mold Co. Ltd.pdf

Contact us for mold tools & molding production for your projects!

Email:info@howemold.com

betty@howemold.com

jenny@howemold.com

Tel.: 86-769-85339899 Fax: 86-0769-85339899

Address.: No.39 HeXing Road, South ShaTou District, ChangAn, DongGuan City,

GuangDong, 523863 China

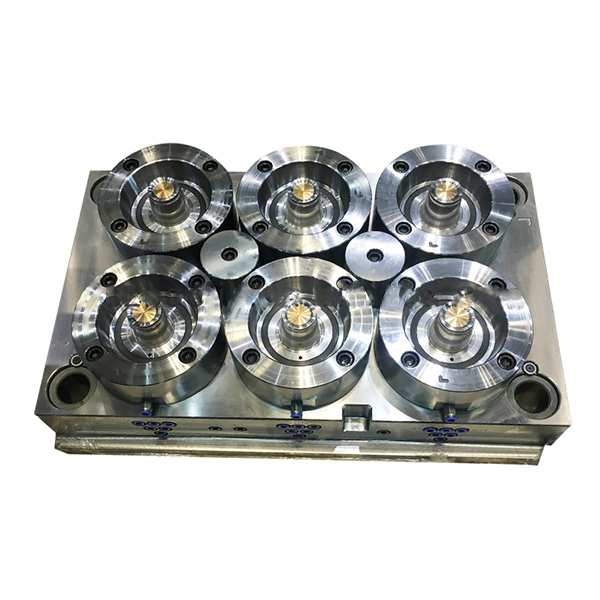

Services: Mold design, Mould manufacturing, Cast die, Tooling,

Molding, Casting, Volume production, Injection plastics, Casted

metalwork, Design and Engineering, Manufacturing and

Production, Molded and Casted Products, Plastics Injection Molding

& Metal Die-Casting, Injection Mold & Cast Mold, Single /

Multi-Cavities Tooling, 2K / 2 Shot / 2 color Multi Shots Mould,

Over Mold, Insert Mould, Compression Mould, Gas-Assisted Mold, 2 /

3 Plates Mold, Volume / Mass / Quantity Production, Testing &

Finishing & Assembling, Rotational Mould, Blow Mold, Stack Mold,

Automotive, Home Appliances, Electronic Products, Consumer Goods,

Industrial Supplies, Machined Parts, Mold

Components, Production Tool

HOWE Precision Mould Co., Ltd. was established in 2011, located in

Changan Town, Dongguan City, which is famous for manufacturing

industry in China. HOWE can provide one-stop solutions from product

design, prototyping, mold making to injection molding and products

assembly. HOWE can produce more than 300 sets of moulds annual

covering many industries such as automotive, electronics, household

appliances, office supplies, fitness equipment, medical care and so

on. We are particularly specialized in high-tech precision

plastic molds and two or multi-color injection molds.

As an experienced technology-oriented company, HOWE has a strong

mold design team, excellent management elites and professional

manufacturing engineers. Equiped with German QUSER high-speed CNC,

Taiwan CNC, precision grinding machines, EDM machines and Fanuc

injection molding machines, HOWE has been dedicated in the R&D

and manufacture of precision molds for years, meanwhile

continuously communicating with experts from Japan, Europe and USA,

learning and innovating, putting advanced theory into practice,

making HOWE technology as good as those best companies in developed

countries.

Since its establishment, HOWE has always adhered to the core values

of "integrity, efficiency, respect, sharing, collaborating and

learning", making unremitting efforts to "become a respectable

supplier". Know ourself, be responsible, keep our word, be

pragmatic and honest are the foundations of our company culture.

Benefits aside, we are making greater efforts to be widely

recognized, to help employees achieve their goals, to contribute to

community, to earn trust and support from each customer.

Shipment: