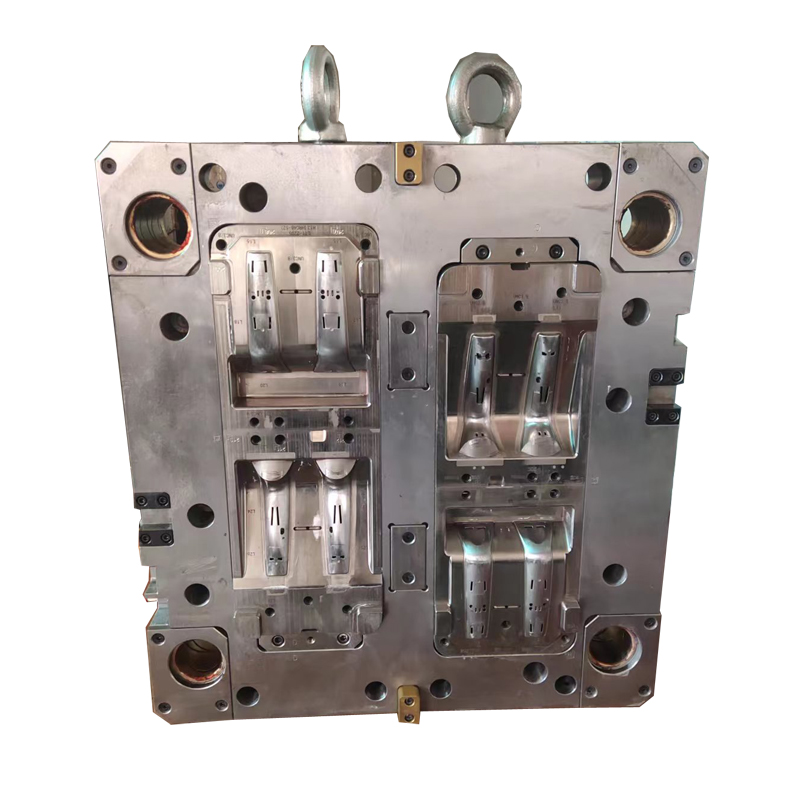

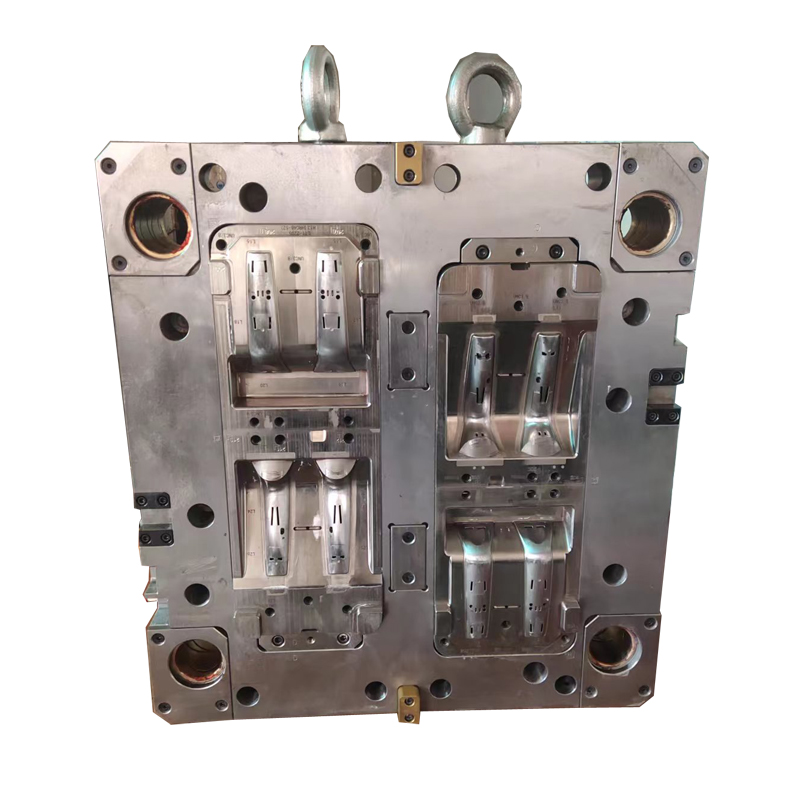

Product Description:

Plastic Injection Tooling is a process of customizing plastic parts

through the injection molding process. It is widely used in

industries such as automotive, electronics, medical, and consumer

products. With Plastic Injection Tooling, you can produce complex

and precise parts that can meet exact customer requirements. This

process is applicable for various sizes and shapes of plastic

components, and the colors can be customized to meet customer

needs.

Plastic Injection Tooling also offers various runner systems such

as the Hot/Cold Runner, and mould bases from well-known suppliers

such as LKM, HASCO, and DME. This ensures that the tooling is of

high quality, and can provide reliable and repeatable results. The

process is highly accurate and repeatable, and the molded parts can

be produced quickly and cost-effectively.

Plastic Injection Tooling is an efficient and cost-effective way to

customize plastic parts. It provides reliable results and combines

the benefits of both plastic injection molding and mold making.

With Plastic Injection Tooling, you can produce high-quality,

customized plastic parts for a wide range of applications.

Features:

- Molding Injection Tooling for Plastic

- Tolerance: ±0.01mm

- Design Software: UG, ProE, Solidworks, AutoCAD

- Lead Time: Depends On The Complexity Of The Product

- CNC Machining: Yes

- Surface Finish: Smooth

Technical Parameters:

| Parameters | Description |

|---|

| Color | Customized |

| Tolerance | ±0.01mm |

| Material | Plastic |

| Design Software | UG, ProE, Solidworks, AutoCAD |

| Runner System | Hot/Cold Runner |

| Process | Injection Moulding |

| Service | OEM/ODM |

| Mould Base | LKM, HASCO, DME |

| CNC Machining | Yes |

| Mould Life | 500,000-1,000,000 Shots |

Applications:

Plastic Injection Tooling is a specialized manufacturing process

used to produce precise and complex parts and components. Howe

HW-824 tooling is specifically designed for injection molding and

is certified for ISO standards. Each set is made from high-quality

material and is built with longevity in mind, ensuring that your

parts will last for many years. Howe HW-824 tooling is designed to

produce single or multi-cavity components and features CNC

machining and a variety of mould bases including LKM, HASCO, and

DME. Customers can also choose between a hot or cold runner system.

The lead time for production depends on the complexity of the

product, and the minimum order quantity is 1 set. Howe HW-824

Plastic Injection Tooling is packaged securely in wooden cases for

moulds and cartons for parts, or other packaging options available

upon request. The price is negotiable, and the supply ability is 60

sets per month. Delivery time is 25 to 40 days, and payment terms

are T/T.

Customization:

Plastic Injection Tooling

Brand Name: Howe

Model Number: HW-824

Place of Origin: Guangdong, China

Certification: ISO

Minimum Order Quantity: 1set

Price: Negotiable

Packaging Details: Wooden case for moulds, cartons for parts, or as

your requirement.

Delivery Time: 25—40 days

Payment Terms: T/T

Supply Ability: 60set/month

Size: Customized

Material: Plastic

Design Software: UG, ProE, Solidworks, AutoCAD

Cavity: Single/Multi

Color: Customized

We specialize in Injection Tooling Molding, Injection Mold Tooling and Plastic Tooling Injection services.

Support and Services:

Plastic Injection Tooling Technical Support and Service

We provide comprehensive technical support and service for plastic

injection tooling. Our experienced engineers and technicians can

help you with any aspect of your project, including:

- Design and manufacture of injection molds

- CAD/CAM design and programming

- Rapid prototyping

- Plastic injection molding process optimization

- Troubleshooting and maintenance

- Material selection and testing

- Quality assurance and controls

We understand that your plastic injection tooling project is unique

and requires specialized attention. That's why our team of experts

is available to provide customized solutions and support that meet

your exact requirements.

Packing and Shipping:

Plastic Injection Tooling Packaging and Shipping:

The plastic injection tooling will be packaged and shipped in a

manner that ensures its safe arrival. The tooling will be secured

in a box and placed on a pallet. The pallet will be wrapped in

stretch film and sealed with a label that includes the customer's

information and the contents of the shipment. The pallet will then

be loaded onto the truck for delivery.

FAQ:

- Q1: What is the brand name of Plastic Injection Tooling?

- A1: The brand name of Plastic Injection Tooling is Howe.

- Q2: What is the model number of Plastic Injection Tooling?

- A2: The model number of Plastic Injection Tooling is HW-824.

- Q3: What is the place of origin of Plastic Injection Tooling?

- A3: The place of origin of Plastic Injection Tooling is Guangdong.

- Q4: Does Plastic Injection Tooling have certification?

- A4: Yes. It has ISO certification.

- Q5: How many sets of Plastic Injection Tooling can be supplied per

month?

- A5: The supply ability of Plastic Injection Tooling is 60 sets per

month.