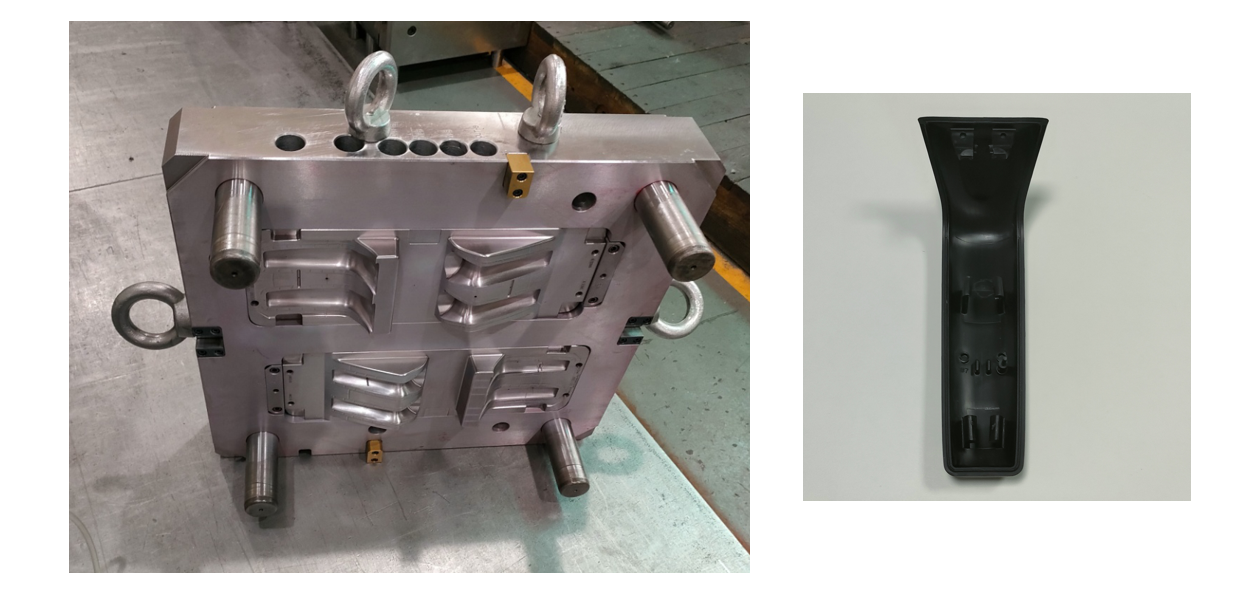

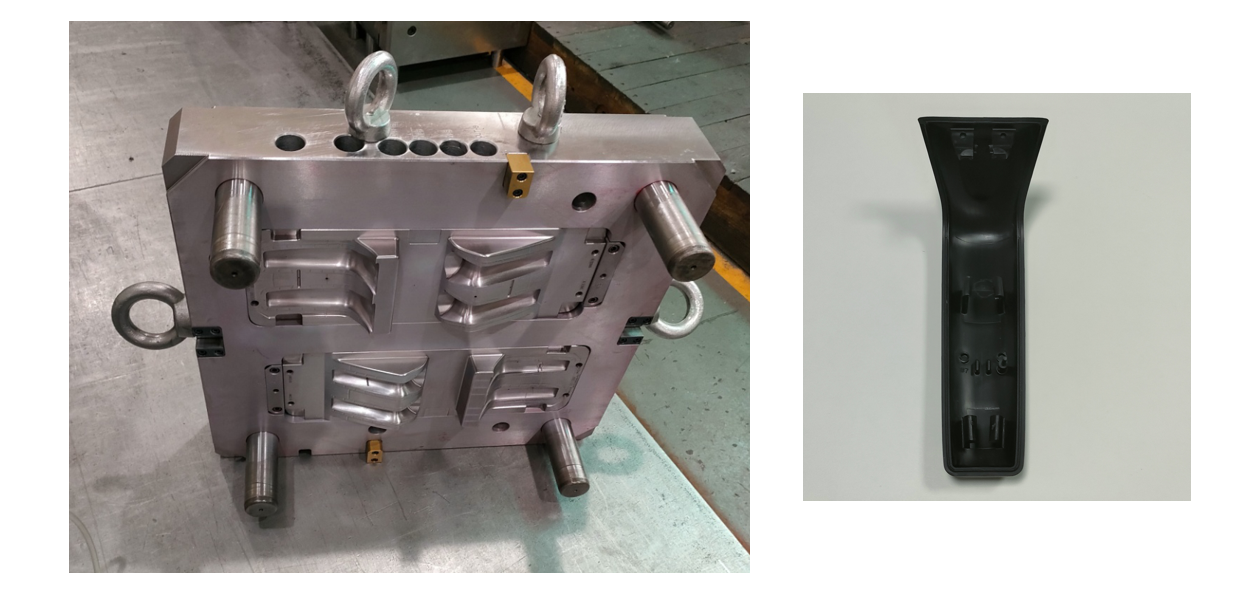

Custom ABS Material Plastic Components Injection Molding

| Product name | Multi cavity hot runner injection mould supplier |

| Mould Material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35,M42,ASP23 |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes,

surface Finish, etc. |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Product Material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV,

TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes,

surface Finish, etc. |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc |

| Mould Cavity | One cavity, multi-cavity or same different products be made

together |

| Runner System | Hot runner and cold runner |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Mould Life | 300-500K shots |

| Mould Precision | +/-0.05mm--+/-0.1mm |

| Producing Process | Audit drawings - mold flow analysis - design validation - Custom

Materials - mold processing - core processing - electrode machining

- Runner system processing - parts processing and procurement -

machining acceptance - cavity surface treatment process - complex

mode Die - The entire mold surface coating - Mounting plate - mold

sample - sample test - sending |

Plastic Mold (Moulds) production process

1. 3d Design/Samples for quotation

2. Start from part design analysis.

3. Mold design drawing and DFM report available so you can see how

is the mold going to be before mold making.

4. If product is complex, moldflow report will be present as well.

5. In house mold making shop ensure you mold quality under well

control.

6. Normally it takes 20-40 days to make mold, precise time depends

on part design.

industrial, consumer, food processing, aviation, seals/gaskets,

lighting, packaging, filter, health care, telecommunications,

mechanical, water treatment, appliance, recreation, lawn and

garden, educational, oil and gas, government, construction,

plumbing, surveillance, pumps, marine, motors, gears, RFID tags,

electronics, and fasteners.

Sample Room

FAQ About plastic injection mould

Q1: What kind of molds do you make? Plastic injection mold,

Compression mold or something else?

A1: We are mainly making plastic injection mold and die-casting

mold.

Sometimes we also make rubber molds according to our customer’s

requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many

different systems, such as DME, Master, Mastip, Hasco, Yudo, Incoe,

Husky, etc.

The manifold recommended for your tool is selected to meet your

individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems we can accept the following files:STP,

IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customer or popular

in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344,

etc.

Q5: Can you provide the steel certificate and heat-treatment

certificate?

A5: Yes, We can provide steel certificate or hardness certificate

to prove.

Q6: Can you make the texture/text/heat-treatment/nitriding for the

injection mold plastic?

A6: Yes, As a plastic mold factory, we have long-term cooperated

subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold’s size and complexity. Normally, the

lead time is 25—45days.

If the Plastic Mouldings are very simple and not big size, we can

work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or

required by clients.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid

moisture.

Third step: We put this plastic film packed mold in a wooden box,

and fix it to avoid any movement.