Product Description:

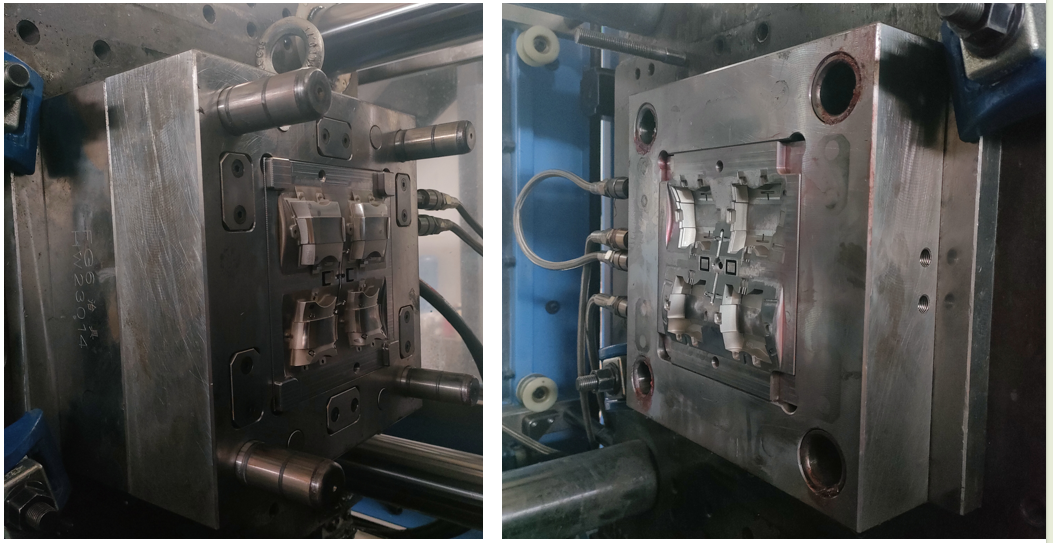

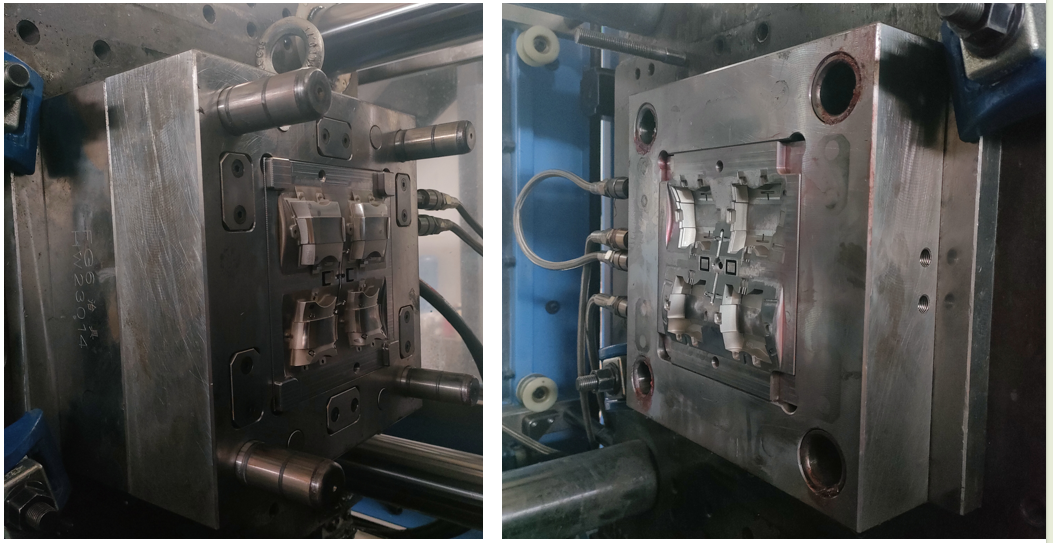

Plastic Injection Tooling is an advanced-technology tooling used

for tooling for plastic molding, molding injection tooling and

other plastic injection molding processes. This tooling is designed

to provide a superior surface finish that is smooth and free of

defects. It is constructed with high quality mould bases from LKM,

HASCO and DME, which are known for their reliability and

durability. The runner system of the tooling can be either hot or

cold runner, depending on the application. The material used is

plastic, which ensures that the tooling is lightweight and

long-lasting. Plastic Injection Tooling is a cost-effective and

high-performance solution for all your plastic injection molding

needs.

Features:

- Product Name: Plastic Injection Tooling

- Color: Customized

- CNC Machining: Yes

- Surface Finish: Smooth

- Process: Injection Moulding

- Cavity: Single/Multi

- Tooling for Plastic Injection

- Injection Tooling Molding

- Injection Molding Tooling

Technical Parameters:

| Product name | Single cavity cold runner injection mould |

| Normal Plastic | PP, PE, EVA, PS; |

| Enginnering Plastic | PA, PA6, PA66, PC+ABS, PA46, PA+30% GF, PC, ABS, POM, PBT, TPU, TUR |

| High Engineering Plastic | PEEK, PPS, PPO, PEI, PES, PLA, LCP, antistatic plastic, etc |

| Mould size | Any size as per customer's requirement |

| Surface Treatment | Polishing/smooth, Texture/frosted, Printing, Painting, Plating |

| Plastic Color | Nature, white, black, red, yellow, blue,green, as per customer's

requirement |

| Products range | Electronic products, industrial products, househould products,

medical device, petrochemical, auto, aerospace, home appliances,

LED lamp parts, agriculture parts. |

| Lead time | 5-30 working days after receiving deposit or L.C |

| Payment we support | T/T, Paypal |

About Us:

HOWE Precision Mould Manufacture Co., Ltd. private-owned

enterprise, with around 2, 000sqm work shop locates in Chang'an

Town, Dong Guan City, Guang Dong Province, China. Which was

established at the beginning of 2010 and it′s only one and a half

hour′s drive from the airport/ ferry port in Hong Kong, Guang Zhou

and Shen Zhen to our factory. Our moulds are mainly exported to

USA, Canada, Brazil, UK, Germany, Spain and Japan etc.,

We have more than 13 years experience in building all kinds of

plastic molds & die casting molds and manufacturing products.

Capability of design, level of manufacturing, and mould quality

system and company target can meet the demands of various

customers. Our molds annual capacity is up to 500sets. Main moulds

cover large automobile components, home electric appliances,

electric garden tools, medical treatment equipment, computer

peripheral parts, telescopes, plastic pipe for drink-water

machines, two colour moulds, etc.

Our factory is equipped with advanced equipment: CNC machines, the

machining range is (550mm - 5000mm), EDM machines, the machining

range is (300mm - 3000mm), High speed CNC machines, CMM, wire-cut

machines, numerical controlled lathers, milling machines,

large-size drilling machines, grinding machines, and deep-hole

drilling machines. We can also provide mold trial and plastic

injection with 50 tons to 2880 tons of Injection Machine and 3600

tons of Plastic Injection Machine.

Workshop:

Support and Services:

Automotive, White goods, furniture industry, Gaming industry,

Household products, medical products.

Any kind of moulds are available:

1. Sample or 2D drawing from customer

2. Build 2D and 3D drawing

3. CAD mould design

4. Parts inspection / CNC machining / EDN machining

5. Mould assembly

6. Mould test

7. Sample confirm

8. Dilver the mould

How ot order from HOWE?

1. Inquiry-Professional quotation.

2. Confirm the price. lead time. artwork. payment term etc.

3. Howe sales send the Proforma Invoice with Howe company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5.Initial Production Stage-Inform the clients that we have got the

payment and will make the samples according to your request, send

you photos or Samples to get your approval. After approval, we

inform that we will arrange the production & inform the estimated

time.

6. Middle Production-send photos to show the production line which

you can see your products in . Confirm the estimated delivery time

again.

7. End Production-Mass production products photos and samples will

send to you for approval. You can also arrange the third party

Inspection .

8. Client make payment for balance and Howe ship the cargo. Also

Howe can accept payment term-Balance against TT,Paypal or D/P

payment Term.

9. Order can be say "finish" when you receive the goods and satisfy

with them .

10. Feedback to Howe about Quality. Service. Market Feedback &

Suggestion. And we can do better .

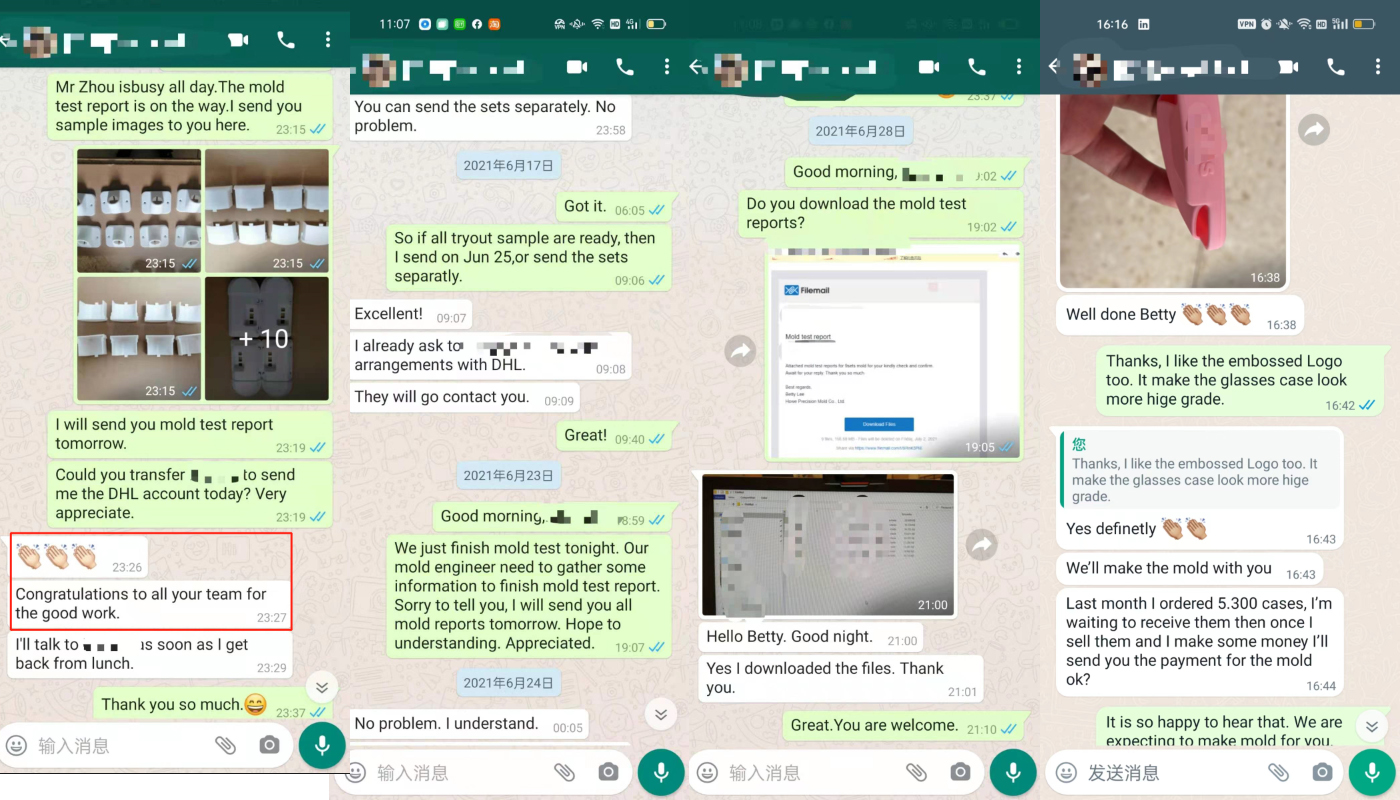

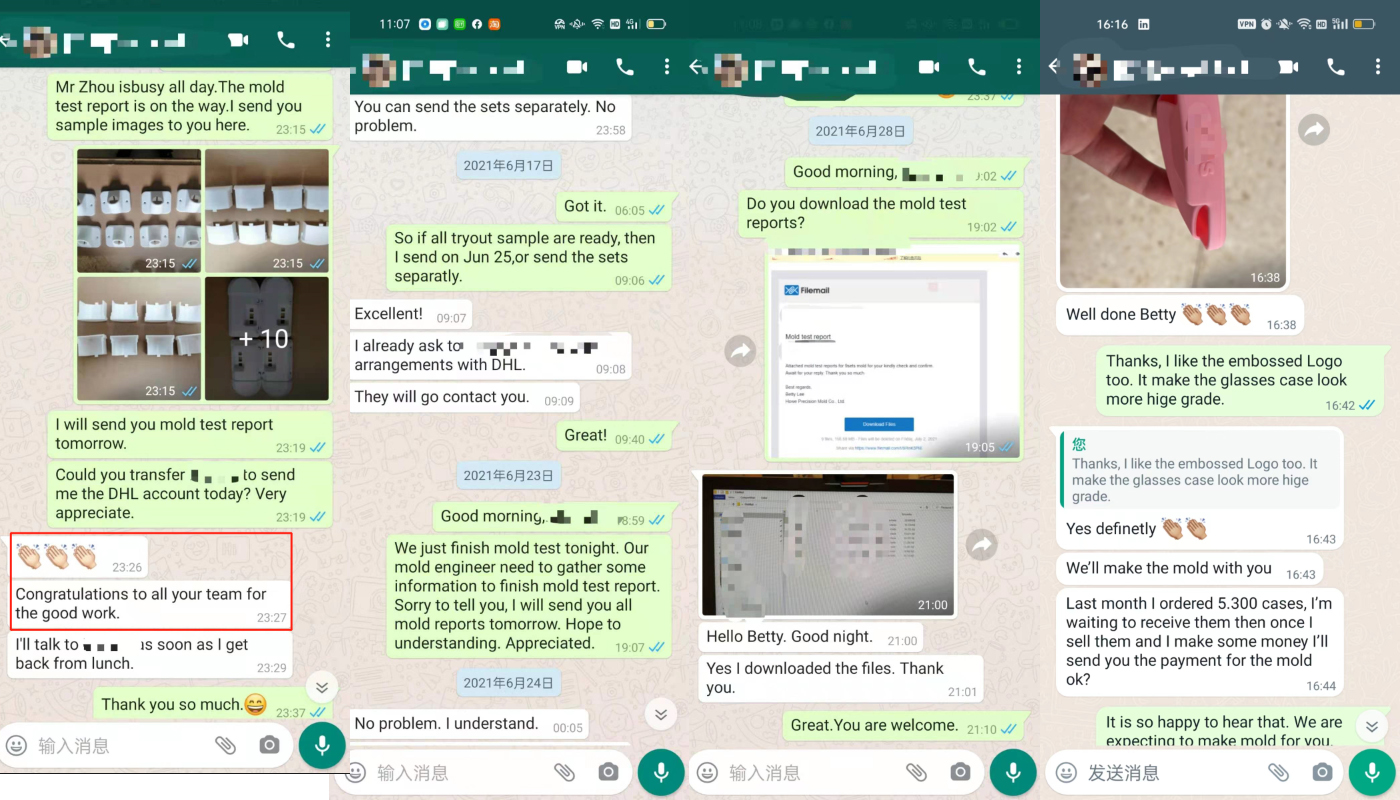

Clients Feedback:

Clients Visiting:

FAQ:

Q1: Are you manufacturer or trading company ?

A1: We are the manufacturer of Injection moulding parts, our price

is more competitive.

Q2: Do you support OEM/ODM service?

A2: Yes, we have a large experienced R&D team, we can offer

one-stop service,so welcome to place OEM/ODM orders to us.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold’s size and complexity.Normally, the

lead time is 25-45 working days.If the plastic moulds are very

simple and in small size, we can work out within 15 days.

Q4: What kind of plastic materials you usually use?

A4: We are specialized in producing plastic products with the

following materials:

PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q5: How do you pack the plastic molded parts?

A5: We pack the plastic molded parts by thick-wall export

cartons.If the finish surface of plastic molded parts requires safe

protection to avoid scratches, we will use bubble plastic bag to

pack the parts.

Q6: How does your factory do regarding quality control?

A6: Secure production under strict quality control system; Quality

is priority. 100% products tested. ISO Certification is available

if required.